Handheld laser welding offers flexibility and mobility that traditional fixed stations cannot match. However, this flexibility also introduces a hidden challenge: constantly changing thermal conditions. As operators move, change speed, adjust angles, or weld thin and reflective materials, the heat load on the laser source fluctuates in real time. Without proper temperature control, these fluctuations can quietly undermine welding quality.

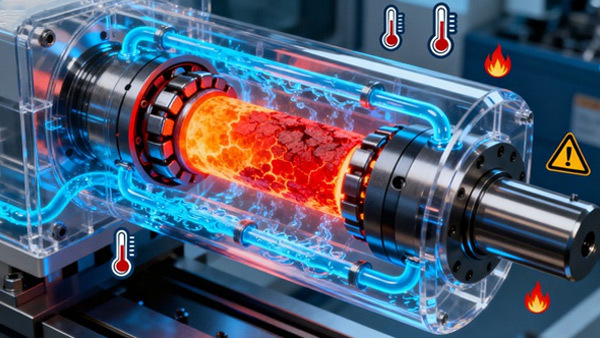

The Invisible Impact of Temperature Fluctuations

Laser sources are highly sensitive to temperature changes. Even a small increase in internal temperature can affect beam stability, leading to oxidation, porosity, or inconsistent weld seams. These issues often appear as quality problems on the surface, while the root cause lies in thermal instability inside the system.

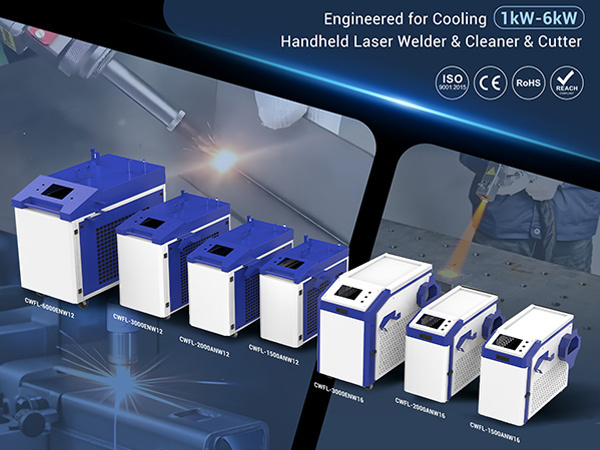

How the RMFL-3000 Manages Heat

The RMFL-3000 handheld laser welding chiller is designed to address these challenges through a precisely controlled refrigeration cycle. Using a closed-loop system that includes a compressor, condenser, throttling device, and plate heat exchanger, the chiller continuously removes excess heat from the laser system. This process maintains a stable operating temperature, even when welding conditions change suddenly.

Dual-Circuit Cooling for Better Control

Handheld laser welders typically require different cooling conditions for the laser source and the welding torch. The RMFL-3000 meets this need with a dual-circuit cooling design, allowing each component to operate within its ideal temperature range. By preventing thermal interference between the two circuits, the chiller minimizes thermal drift and helps maintain consistent beam focus and energy delivery.

Consistent Welding Starts with Stable Cooling

Effective temperature control plays a key role in achieving repeatable, high-quality welding results. By stabilizing the laser’s thermal environment, the RMFL-3000 supports cleaner welds, reduces rework, and improves efficiency during long production runs. In handheld laser welding, where operating conditions are rarely constant, reliable cooling becomes an essential part of the system rather than an afterthought.

Source: https://www.teyuchiller.com/how-the-teyu-rack-chiller-stabilizes-handheld-laser-welding.html