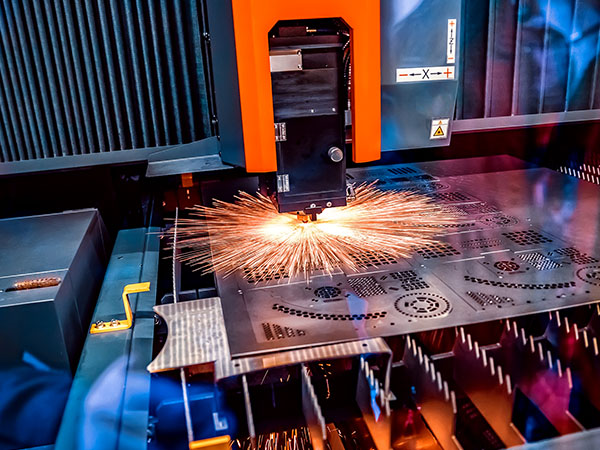

Laser technology has advanced rapidly over the past few decades. From nanosecond laser to picosecond laser to femtosecond laser, it has been gradually applied in industrial manufacturing, providing solutions for all walks of life. But how much do you know about these 3 types of lasers? Let's find out together:

Definitions of Nanosecond, Picosecond, and Femtosecond Lasers

Nanosecond laser was first introduced into the industrial field in the late 1990s as diode-pumped solid-state (DPSS) lasers. However, the first such lasers had a low output power of a few watts and a wavelength of 355nm. Over time, the market for nanosecond lasers has matured, and most lasers now have pulse durations in tens to hundreds of nanoseconds.

Picosecond laser is an ultra-short pulse width laser that emits picosecond-level pulses. These lasers offer an ultra-short pulse width, adjustable repetition frequency, high pulse energy, and are ideal for applications in biomedicine, optical parametric oscillation, and biological microscopic imaging. In modern biological imaging and analysis systems, picosecond lasers have become increasingly important tools.

Femtosecond laser is an ultra-short pulse laser with an incredibly high intensity, calculated in femtoseconds. This advanced technology has provided humans with unprecedented new experimental possibilities and has broad applications. The utilization of an ultra-strong, short-pulsed femtosecond laser for detection purposes is particularly advantageous for various chemical reactions, including but not limited to bond cleavage, new bond formation, proton and electron transfer, compound isomerization, molecular dissociation, speed, angle, and state distribution of reaction intermediates and final products, chemical reactions occurring in solutions and the impact of solvents, as well as the influence of molecular vibration and rotation on chemical reactions.

Time Conversion Units for Nanoseconds, Picoseconds, and Femtoseconds

1ns (nanosecond) = 0.0000000001 seconds = 10-9 seconds

1ps (picosecond) = 0.0000000000001 seconds = 10-12 seconds

1fs (femtosecond) = 0.000000000000001 seconds = 10-15 seconds

The nanosecond, picosecond, and femtosecond laser processing equipment commonly seen in the market are named based on time. Other factors, such as single pulse energy, pulse width, pulse frequency, and pulse peak power, also play a role in selecting the appropriate equipment for processing different materials. The shorter the time, the less impact on the material surface, resulting in a better processing effect.

Medical Applications of Picosecond, Femtosecond, and Nanosecond Lasers

Nanosecond lasers selectively heat and destroy melanin in the skin, which is then eliminated from the body by the cells, resulting in the fading of pigmented lesions. This method is commonly used for the treatment of pigmentation disorders. Picosecond lasers operate at a high speed, breaking down melanin particles without damaging the surrounding skin. This method effectively treats pigmented diseases such as nevus of Ota and Brown cyan nevus. Femtosecond laser operates in the form of pulses, which can emit huge power in an instant, great for the treatment of myopia.

Cooling System for Picosecond, Femtosecond, and Nanosecond Lasers

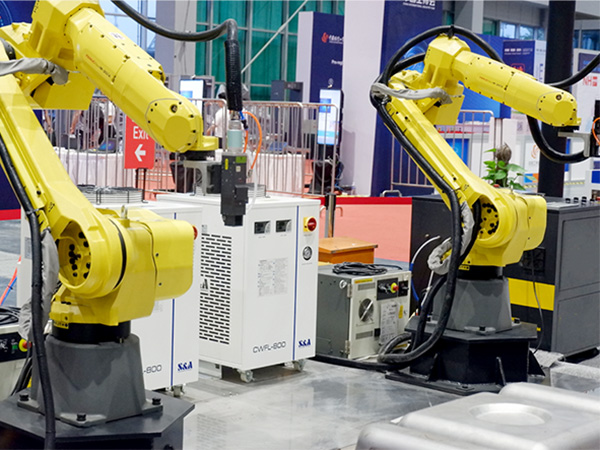

No matter the nanosecond, picosecond or femtosecond laser, it is necessary to ensure the normal operation of the laser head and pair the equipment with a laser chiller. The more precise the laser equipment, the higher the temperature control accuracy. TEYU ultrafast laser chiller has a temperature stability of ±0.1°C and rapid cooling, which ensures that the laser works at a constant temperature and has a stable beam output, thereby improving the service life of the laser. TEYU ultrafast laser chillers are suitable for all these three types of laser equipment.

Source: https://www.teyuchiller.com/the-differences-between-nanosecond-picosecond-and-femtosecond-lasers