A laser dicing machine is an efficient and precise cutting device that utilizes laser technology to instantaneously irradiate materials with high energy density. This causes instant heating and expansion of the material, creating thermal stress and enabling precise cutting. It boasts high cutting precision, non-contact slicing, absence of mechanical stress, and seamless cutting, among other significant advantages, and thus finds wide application across various fields.

Several Primary Application Areas of Laser Dicing Machines Include:

1. Electronics Industry

Laser dicing technology plays a crucial role in producing integrated circuits. It offers advantages such as fine line width, high precision (line width of 15-25μm, groove depth of 5-200μm), and fast processing speed (up to 200mm/s), achieving a yield rate of over 99.5%.

2. Semiconductor Industry

Laser dicing machines are used for cutting semiconductor integrated circuits, including slicing and dicing of single and double-sided glass-passivated diode wafers, single and double-sided silicon-controlled wafers, gallium arsenide, gallium nitride, and IC wafer slicing.

3. Solar Energy Industry

Due to minimal thermal impact and high precision, laser dicing is widely applied in the photovoltaic industry for slicing solar cell panels and silicon wafers.

4. Optoelectronics Industry

Laser dicing machines are employed in cutting optical glass, optical fibers, and other optoelectronic devices, ensuring cutting precision and quality.

5. Medical Equipment Industry

Laser dicing machines are used for cutting metals, plastics, and other materials in medical equipment, meeting the precision and quality requirements of medical instruments.

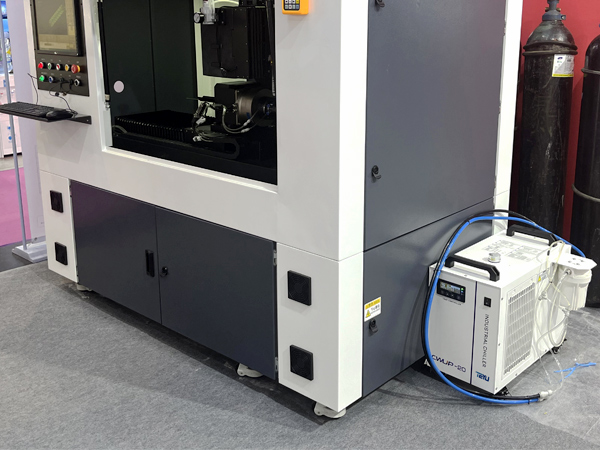

The Configuration of Laser Chiller for Laser Dicing Machines

During the process of laser dicing, a considerable amount of heat is generated. This heat can have adverse effects on the dicing process and might even damage the laser itself. A laser chiller maintains the laser dicing process within an appropriate temperature range, ensuring accuracy, and stability, and effectively extending the lifespan of the laser dicing machine. It's an essential cooling device for laser dicing machines.

TEYU S&A laser chillers cover cooling capacities from 600W to 42000W, offering precise temperature control precision of up to ±0.1℃. They can perfectly meet the cooling requirements of laser dicing machines available in the market. With 22 years of experience in chiller manufacturing, TEYU S&A Chiller Manufacturer has an annual shipment exceeding 150,000 water chiller units. Each laser chiller undergoes rigorous standardized testing and comes with a 2-year warranty. Feel free to reach out via sales@teyuchiller.com to select the best cooling solution for your laser dicing machine.

没有评论:

发表评论