1. What Is An Industrial Chiller?

An industrial chiller is a cooling device that provides constant temperature, constant current and constant pressure, and lowers the temperature of machinery/industrial spaces by removing heat from the system and transferring it elsewhere.

2. Why Do You Need An Industrial Chiller?

No industrial process, machine, or motor is 100% efficient, and heat buildup is the main cause of inefficiency. The heat will accumulate over time causing reduced production times, equipment shutdowns, and even premature equipment failure. An industrial chiller is necessary to incorporate into the industrial process system to avoid these issues.

Premium industrial chillers can optimize the product processing process and quality, increase production efficiency and the lifespan of laser equipment, reducing product losses and machine maintenance costs. Using a professional industrial chiller has numerous benefits. It is a wise choice to ensure stable operation and ultimately improve industrial profits. TEYU S&A Chiller with a 21-year dedication to industrial chillers is confident to provide premium chillers and reliable after-sales service.

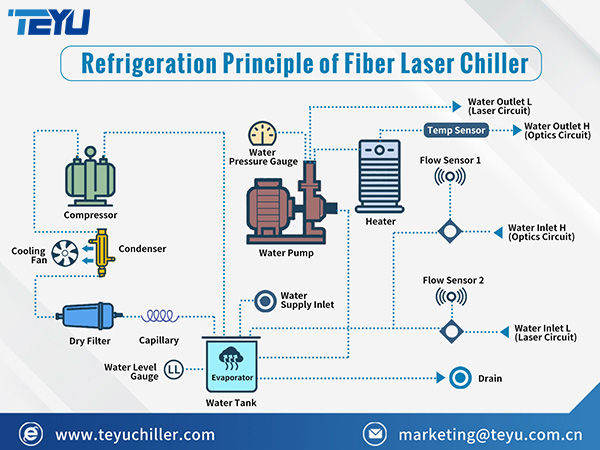

3. How Does An Industrial Chiller Work?

Refrigeration Principle Of Industrial Chiller For Supporting Equipment: The industrial chiller's refrigeration system cools the water, and the water pump delivers the low-temperature cooling water to the equipment that needs to be cooled. As the cooling water takes away the heat, it heats up and returns to the industrial chiller, where it's cooled again and transported back to the equipment.

Refrigeration Principle Of The Water Chiller Itself: In the industrial chiller's refrigeration system, the refrigerant in the evaporator coil absorbs the heat of the return water and vaporizes it into steam. The compressor continuously extracts the generated steam from the evaporator and compresses it. The compressed high-temperature, high-pressure steam is sent to the condenser and later releases heat (heat extracted by the fan) and condenses into a high-pressure liquid. After being reduced by the throttling device, it enters the evaporator to be vaporized, absorbs the heat of the water, and the whole process circulates constantly.

4. Classification of Industrial Chillers

According to the industrial chiller's heat dissipation method, it is mainly divided into air-cooled chillers and water-cooled chillers.

According to the chiller compressors' different classifications, it is mainly divided into piston chillers, scroll chillers, screw chillers and centrifugal chillers.

According to the outlet water temperature of industrial chillers: there are mainly room-temperature chillers, low-temperature chillers and ultra-low-temperature chillers.

According to the cooling capacity of industrial chillers, it's mainly divided into small chillers, medium chillers and large chillers.

5. Cooling Applications of Industrial Chillers

Industrial chillers have been used in more than 100 industries such as the laser industry, chemical industry, mechanical processing manufacturing industry, automobiles, electronics, machinery, aviation, plastic manufacturing, metal plating, food production, medical industry, textile printing, and dyeing industry, etc. With the changing demands of the market for temperature control, the cooling applications of industrial chillers in various industries are constantly being broadened and extended.

TEYU S&A Chiller is an industrial chillers manufacturer and supplier with laser as the target application. Since 2002, we have been focusing on the cooling need from fiber lasers, CO2 lasers, ultrafast lasers and UV lasers, etc. Other industrial applications of our recirculating water chillers include CNC spindles, machine tools, UV printers, vacuum pumps, MRI equipment, induction furnaces, rotary evaporators, medical diagnostic equipment and other equipment that requires precise cooling.

6. How to Choose An Industrial Chiller?

Generally, choose the most suitable and cost-effective chiller according to various indicators such as your industry, required cooling capacity, temperature control accuracy requirements, budget, etc. The following points will help you quickly choose high-quality industrial chiller products: (1)A good-quality industrial chiller can cool down to the temperature set by the user in the shortest time because the range of space temperature needs to be lowered is different. (2)A good-quality industrial chiller controls the temperature precisely. (3)A good-quality industrial chiller can alert timely to remind users to handle the problem quickly and protect equipment safety and production stability. (4) An industrial chiller consists of a compressor, evaporator, condenser, expansion valve, water pump, etc. The quality of components also determines the industrial chiller quality. (5)Qualified industrial chiller manufacturer boasts scientific test standards, so their chiller quality is relatively stable.

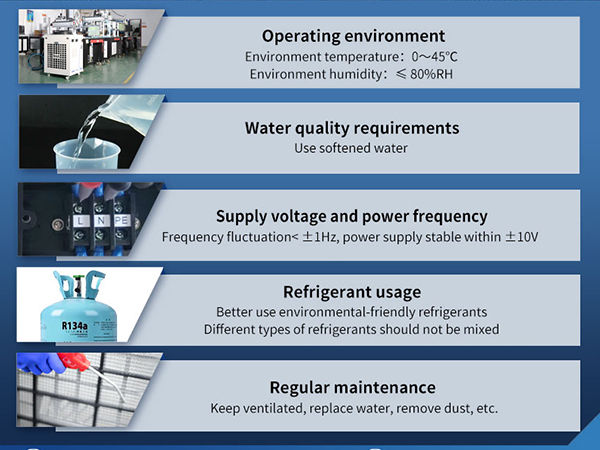

7. Precautions for Using An Industrial Chiller

What should be paid attention to when using industrial chillers? Here are five main points: (1)Recommended environment temperature range from 0℃~45℃, environment humidity of ≤80%RH. (2)Use purified water, distilled water, ionized water, high-purity water and other softened water. But oily liquids, liquids containing solid particles, and liquids corrosive to metals are prohibited. (3)Match the power frequency of the chiller according to the usage situation and ensure that the frequency fluctuation is less than ±1Hz. For long time operation, the power supply is recommended to be stable within ±10V. Keep away from electromagnetic interference sources. Use the voltage regulator and variable-frequency power source when necessary. (4)Use the same type of the same refrigerant brand. The same type of different refrigerant brands can be mixed to use, but the effect may be weakened. Different types of refrigerants should not be mixed. (5)Regular maintenance: keep a ventilated environment; replace the circulating water and remove dust regularly; shut down on holidays, etc.

8. Industrial Chiller Maintenance Tips

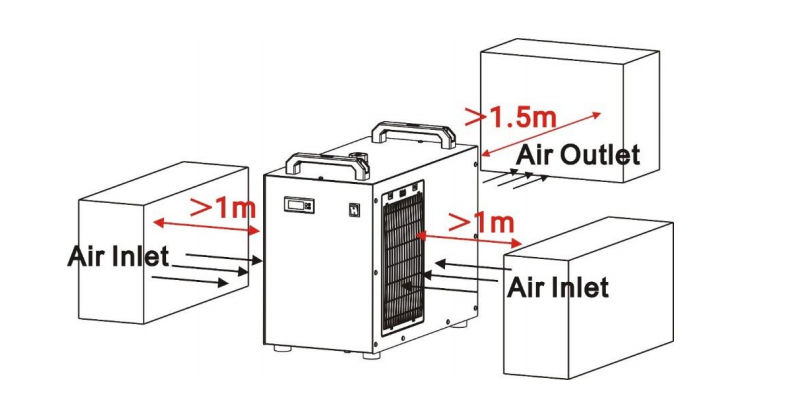

Summer Maintenance Tips of Industrial Chiller: (1)Avoid high-temperature alarms: Adjust the chiller's working environment to maintain the optimal ambient temperature between 20℃-30℃. Regularly use an air gun to clean the dust on the industrial chiller's filter gauze and condenser surface. Maintain a distance of more than 1.5m between the chiller's air outlet (fan) and obstacles and a distance of more than 1m between the chiller's air inlet (filter gauze) and obstacles to facilitate heat dissipation. (2)Regularly clean the filter screen as it is where dirt and impurities accumulate the most. If it is too dirty, replace it to ensure stable water flow of the industrial chiller. (3)Regularly replace the circulating water with distilled or purified water in summer if antifreeze was added in winter. This prevents residual antifreeze from affecting equipment operation. Replace the cooling water every 3 months and clean pipeline impurities or residues to keep the water circulation system unobstructed. (4)If the circulating water temperature is lower than the ambient temperature, condensing water may be generated on the surface of the circulating water pipe and cooled components. condensing water can cause a short circuit of the equipment's internal circuit boards or damage the core components of the industrial chiller, which will affect production progress. It is recommended to adjust the set water temperature based on the ambient temperature and laser operating requirements.

Winter Maintenance Tips of Industrial Chiller: (1)Keep the industrial chiller in a ventilated position and remove the dust regularly. (2)Replace circulating water at regular intervals. It's recommended to replace the circulating water once every 3 months. And it's better to select purified water or distilled water to reduce the limescale formation and keep the water circuit smooth. (3)If you don’t use the water chiller in winter, drain the water from the chiller and store the chiller properly. You can cover the machine with a clean plastic bag to prevent dust and moisture from entering the equipment. (4)For areas below 0℃, antifreeze is needed for chiller operation in winter.

9. Common Faults and Solutions of Industrial Chillers

1)Incorrect Chiller Model: The incorrect chiller model has a great impact on industrial processing. You can choose a suitable industrial chiller according to the required cooling capacity, temperature control accuracy, flow rate, budget and other factors. Under the condition of a sufficient budget, try to choose a chiller with a large cooling capacity to cope with the increased cooling demand in hot summer. You can consult the professional team of the industrial chiller manufacturer to avoid incorrect chiller models.

2)Improper Operation: The manufacturer’s instructions for correctly operating industrial chillers are included in the manuals that come with them. Please use it in strict accordance with the instruction manual of the industrial chiller. Correct operation can maintain the effectiveness and service life of the equipment.

3)Maintenance Neglect: Industrial chillers have a lot of maintenance guides, and the common daily maintenance includes maintaining the correct use environment, regular inspection of parts, regular replacement of circulating water, regular dust removal, etc.

4)Other Common Issues

Incorrect thermostat setting: The chiller may not be able to maintain the desired temperature if the thermostat is not set to the proper temperature. Adjust the thermostat setting as necessary to solve this issue.

Chiller Won’t Start: If there is an issue with the electrical supply, such as a loose wire, blown fuse, or tripped circuit breaker, the chiller may not turn on. A broken control panel or thermostat could prevent the chiller from starting. Low refrigerant levels or a leak could prevent the chiller from starting. A failing motor or a seized compressor may prevent the chiller from starting. A broken part or damaged belt may cause the chiller not to start. It’s critical to find and fix the root cause of the problem if the chiller won’t start. And you can call a professional for repair in some circumstances.

Pump Failure: If the pump has failed, the chiller won’t operate correctly since it can’t circulate refrigerant. You need to fix or replace the pump to solve this issue.

Compressor Failure: If the compressor has failed, the chiller won’t be able to cool efficiently since it won’t be able to circulate refrigerant. You need to fix or replace the compressor to solve this issue.

Condenser Coils Clogged: It's hard for a chiller to effectively dissipate heat when the condenser coils are unclean or clogged and resulting in improper cooling. You need to clean regularly or change the clogged condenser coils to resolve this issue.

High-pressure alarm: (1)Clogging in the filter gauze will lead to insufficient heat radiation. To solve this problem, you can remove the gauze and clean it regularly, keeping good ventilation for air inlet and outlet. (2)Blockage in the condenser may cause a high-pressure failure in the cooling system. It is necessary to do periodic cleaning. (3)Excessive refrigerant: the refrigerant should be released until normal according to the suck and exhaust pressure, balance pressure, and running currently under rated working conditions. (4)Air is mixed in the cooling system and stays in the condenser causing condensation failure and a rise in pressure. The solution is to degas through the air separating valve, air outlet, and the condenser of the chiller.

For some other chiller failures, such as high-temperature alarm, water flow alarm, low water level, etc., follow the corresponding methods to solve these problems. If you can't solve it yourself, you can ask the after-sales team of the chiller manufacturer for professional maintenance knowledge.

Source: https://www.teyuchiller.com/what-is-an-industrial-chiller-and-how-does-it-work