Router is an indispensable part of CNC machines which perform high speed milling, drilling, engraving, etc..

But high speed rotation of the spindle relies on proper cooling. If the heat dissipation problem of the spindle is ignored, some serious problems might occur, from shorter working life to completely shutting down.

There are two common cooling methods in CNC router spindle. One is water cooling and the other is air cooling. As their names suggest, air cooled spindle uses fan to dissipate the heat while water cooled spindle uses water circulation to take away the heat from the spindle. What would you choose? Which is more helpful?

There are a few factors you should consider when choosing the cooling method.

1.Cooling effect

For water cooled spindle, its temperature often remains less than 40 degree Celsius after water circulation, which means water cooling offers a choice of temperature adjustment. Therefore, for CNC machines which require long-period running, water cooling is more suitable than air cooling.

2.Noise problem

As mentioned before, air cooling uses fan to dissipate the heat, so air cooled spindle has serious noise problem. On the contrary, water cooled spindle uses water circulation which is pretty quiet during working.

3.Lifespan

Water cooled spindle often has a longer lifespan than air cooled spindle. With regular maintenance like water changing and dust removing, your CNC router spindle can have a longer life.

4.Working environment

Air cooled spindle can basically work at any working environment. But for water cooled spindle, it needs special treatment in winter or at places which are pretty cold all year around. By special treatment, it refers to adding anti-freeze or heater to keep the water from freezing or rising temperature quickly, which is quite easy to do.

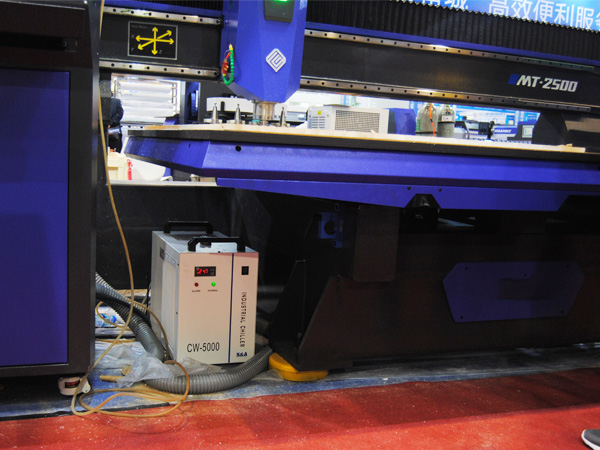

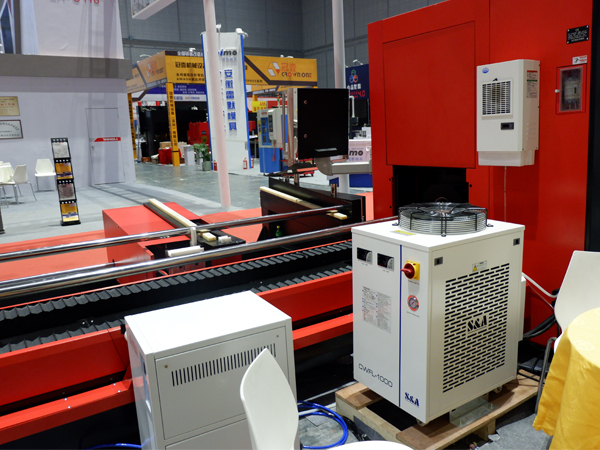

Water cooled spindle often requires a chiller to provide water circulation. And if you are looking a spindle chiller, then S&A CW series might be suitable for you.

CW series spindle chillers are applicable to cool CNC router spindles from 1.5kW to 200kW. These CNC machine coolant chillers offer cooling capacity ranging from 800W to 30KW and stability up to ±0.3℃. Multiple alarms are designed to protect the chiller and spindle as well. There are two temperature control modes available for selection. One is constant temperature mode. Under this mode, water temperature can be manually set to remain at a fixed temperature. The other is intelligent mode. This mode enables automatic temperature adjustment so that the temperature difference between the room temperature and the water temperature won’t be too much.

Find out the complete CNC router chiller models at https://www.teyuchiller.com/cnc-spindle-chillers_c5