When users search for "laser chiller", they are often facing a practical problem rather than simply looking for a product. Common concerns include unstable laser output, inconsistent processing quality, unexpected shutdowns, or shortened laser source lifespan. Behind many of these issues lies one critical factor: insufficient or unstable thermal management.

A laser chiller is not just an auxiliary device. It plays a direct role in how efficiently, accurately, and reliably a laser system performs. Understanding how laser cooling works and how different cooling requirements arise helps users quickly identify the most suitable chiller solution for their equipment.

The Relationship Between Temperature and Laser Performance

Laser systems convert electrical energy into optical energy, and during this process, a significant portion of energy is released as heat. If this heat is not removed in a controlled manner, several performance issues may occur:

* Laser power drift caused by temperature-sensitive laser gain media

* Beam quality degradation, affecting cutting edges or weld seams

* Reduced repeatability in marking or micro-processing applications

* Accelerated aging of laser sources and optics

A stable laser chiller maintains the cooling water at a controlled temperature, ensuring that thermal conditions remain consistent even during long production cycles. This stability is essential for achieving predictable, repeatable laser results.

Why General Cooling Is Not Enough for Laser Systems

Many users initially consider basic cooling methods such as fans, open water tanks, or general-purpose industrial chillers. However, laser systems impose unique cooling demands:

* Continuous heat generation rather than intermittent loads

* High sensitivity to temperature fluctuation, especially in fiber, UV, and ultrafast lasers

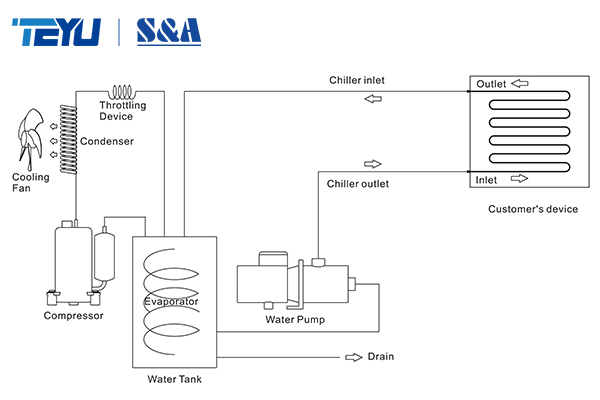

* Need for closed-loop, clean water circulation to protect internal cooling channels

A dedicated laser chiller is designed to address these requirements by combining refrigeration, precise temperature control, flow monitoring, and system protection in a single closed-loop unit.

How Laser Chillers Are Matched to Different Laser Technologies

* Cooling Requirements for CO₂ Laser Equipment

CO₂ lasers typically operate for extended periods and require steady water flow to maintain tube or RF module temperature. Temperature stability directly affects laser output consistency. In these applications, industrial water chillers with reliable refrigeration performance and moderate temperature precision are commonly used to support uninterrupted operation.

* Cooling Challenges in Fiber Laser Systems

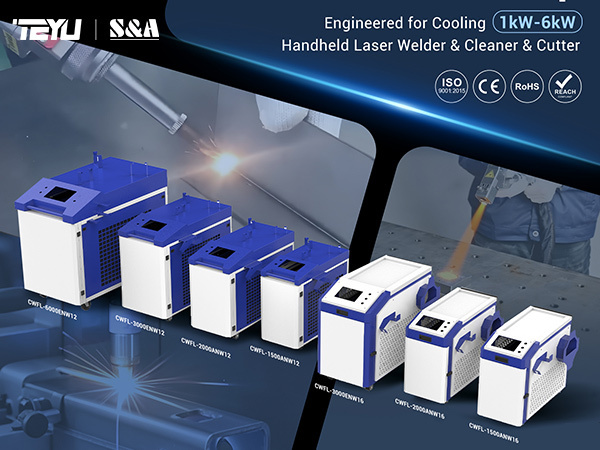

Fiber lasers concentrate high power into compact structures, resulting in high thermal density. As laser power increases, heat must be removed from both the laser source and optical components. This is why fiber laser cooling often relies on dual-circuit laser chiller designs, allowing independent temperature control for different parts of the system.

* Precision Cooling for UV and Ultrafast Lasers

In UV, picosecond, and femtosecond laser applications, even small temperature changes can affect wavelength stability and pulse characteristics. These systems demand high-precision laser chillers capable of maintaining extremely stable water temperatures. Precision cooling becomes a key factor in achieving micron-level processing accuracy and consistent experimental results.

How Laser Chillers Contribute to Equipment Longevity

One of the most overlooked benefits of a laser chiller is its impact on long-term equipment reliability. Stable thermal conditions help to:

* Reduce thermal stress on laser diodes and optical coatings

* Prevent internal scaling or corrosion caused by poor water control

* Minimize unexpected downtime due to overheating alarms

* Extend maintenance intervals and overall system service life

In this sense, a laser chiller acts as both a performance enhancer and a protective system for valuable laser equipment.

Key Factors to Consider When Selecting a Laser Chiller

Rather than focusing only on cooling capacity, users should evaluate a laser chiller based on real operating conditions:

* Total heat load and laser power level

* Required temperature stability for the specific laser technology

* Flow rate and pressure compatibility with the laser system

* Installation environment and space constraints

* Monitoring, alarm, and protection functions

Matching these factors ensures that the chiller supports the laser system effectively without over-sizing or under-performing.

Finding the Right Laser Chiller Solution

A well-matched laser chiller is not defined by a single parameter but by how well it aligns with the laser's operating characteristics and application goals. From industrial cutting and welding to precision micro-processing and laboratory research, different laser systems require different cooling strategies.

By understanding how temperature affects laser behavior and why dedicated laser chillers are designed the way they are, users can more confidently identify a cooling solution that improves performance, stability, and equipment lifespan.

Final Thoughts

Searching for "laser chiller" is often the first step toward solving deeper performance and reliability challenges in laser applications. A clear understanding of laser cooling principles helps users move beyond trial-and-error and toward a solution that supports long-term, stable operation.

Choosing the right laser chiller is not just about cooling—it is about enabling laser systems to perform at their full potential, day after day.

Source: https://www.teyuchiller.com/laser-chiller-solutions-how-proper-cooling-improves-laser-performance-lifespan.html