Laser cladding is quickly becoming an essential process in modern manufacturing. Known for enhancing surface performance, repairing high-value components, and extending equipment lifespan, it is now widely used across aerospace, automotive, energy, and heavy industry. As global manufacturers pursue smarter and more sustainable production, laser cladding continues to gain strategic importance.

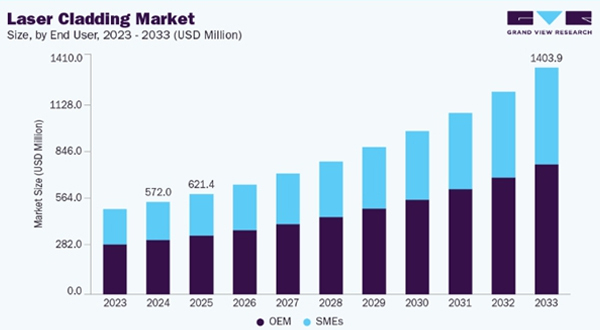

Industry research shows steady growth, with the global laser cladding market expected to expand significantly over the next decade. Beyond equipment sales, service-based applications such as repair and protective coating are growing even faster. Automation, robotics integration, and digital monitoring are also helping companies achieve higher efficiency and more consistent results.

One often overlooked factor behind successful cladding is thermal management. Laser cladding generates intense heat, and without proper cooling, manufacturers may face unstable processing, component deformation, and reduced laser lifespan. Industrial chillers help dissipate heat, stabilize process parameters, and protect sensitive laser components, supporting reliable and repeatable production. Solutions developed specifically for laser applications — including fiber laser chillers widely used in cladding systems — contribute to improved process stability and long-term equipment performance.

Looking ahead, laser cladding is expected to move further toward intelligent automation and green manufacturing. While challenges such as high initial investment and technical complexity remain, the technology’s ability to enhance durability, reduce waste, and improve efficiency positions it as a key process for future industrial development. Reliable cooling systems will continue to play a vital role in ensuring consistent quality and operational stability as adoption grows.

Source: https://www.teyuchiller.com/global-evolution-of-laser-cladding-and-the-role-of-cooling-systems.html

没有评论:

发表评论