During summer chiller usage, ultrahigh water temperature or cooling failure after long-time operation might stem from incorrect chiller selection, external factors, or internal malfunctions of the industrial water chiller.

1. Proper Chiller Matching

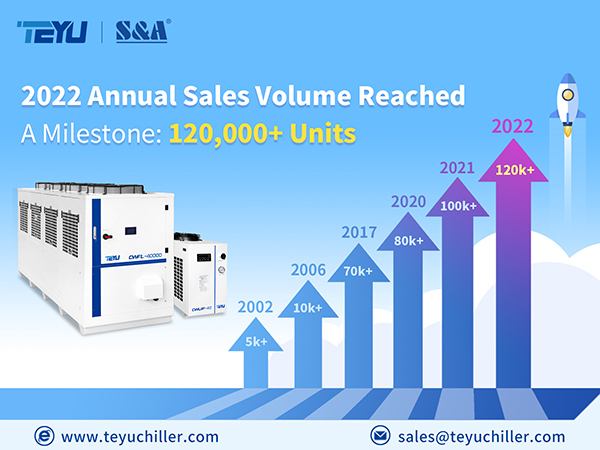

When selecting a water chiller, ensure it aligns with your laser equipment’s power and cooling requirements. This guarantees effective cooling, normal equipment operation, and a prolonged lifespan. With 21 years of experience, TEYU S&A team can expertly guide your chiller selection.

2. External Factors

When the temperature exceeds 40°C, industrial chillers struggle to effectively convert heat, leading to poor heat dissipation within the refrigeration system. It is recommended to position the chiller in an environment with a room temperature below 40°C and good ventilation. Optimal operation occurs between 20°C and 30°C.

Summer marks a peak in electricity consumption, causing fluctuations in grid voltage based on actual power usage; excessively low or high voltages can disrupt equipment's regular operation. It is recommended to utilize a stable voltage, such as a single-phase supply at 220V or three-phase supply at 380V.

3. Inspecting the Internal System of the Industrial Chiller

(1)Verify if the chiller's water level is adequate; Add water up to the highest level of the green zone on the water level indicator. During the chiller installation, ensure that there's no air inside the unit, water pump, or pipelines. Even a small amount of air can disrupt the chiller's operation.

(2)Insufficient refrigerant in the chiller can impair its cooling performance. If a refrigerant shortage occurs, contact our customer service technicians to locate leaks, perform necessary repairs, and recharge the refrigerant.

(3)Monitor the compressor. Prolonged compressor operation might lead to issues like aging, increased clearances, or compromised seals. This results in reduced actual exhaust capacity and a decline in the overall cooling performance. Additionally, anomalies like decreased capacitance or internal irregularities of the compressor can also cause cooling abnormalities, necessitating maintenance or replacement of the compressor.

4. Strengthening Maintenance for Optimal Cooling Efficiency

Regularly clean dust filters and condenser grime, and replace circulating water to prevent inadequate heat dissipation or pipeline blockages that could reduce cooling efficiency.

To maintain chiller functionality, it’s also important to monitor the ambient temperature and humidity changes, inspect electrical circuits regularly, provide proper space for heat dissipation, and conduct comprehensive safety inspections before restarting long-inactive equipment.

For more about TEYU S&A chiller maintenance, please click Chiller Troubleshooting. If you encounter any problems while using our chiller, please don't hesitate to contact our customer service team at service@teyuchiller.com for assistance.

Source: https://www.teyuchiller.com/addressing-summer-cooling-challenges-for-industrial-water-chillers