The efficient operation of fiber lasers heavily relies on precise temperature control, so that the 1500W fiber laser chiller assumes significance, offering unparalleled cooling capabilities and ensuring stable performance.

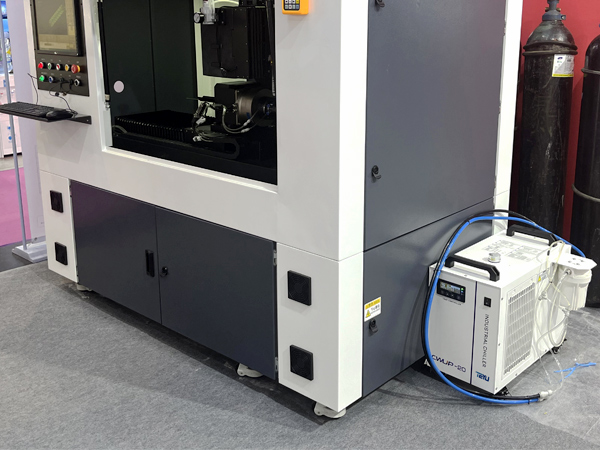

TEYU 1500W fiber laser chiller CWFL-1500 is a cutting-edge cooling solution, designed to cater to the specific cooling needs of 1500W fiber laser applications. It offers highly efficient and reliable active cooling for maintaining fiber laser's optimal operating temperatures, thus enhancing the overall performance and stability of fiber lasers. The unique dual cooling channel design makes it efficient to cool the laser source and the optics/laser gun simultaneously and independently.

Thanks to its advanced heat sinks and heat pipes that effectively transfer heat away from the laser, the 1500W fiber laser chiller CWFL-1500 ensures consistent cooling for the 1500W fiber laser, enhancing its operational efficiency and prolonging its lifespan by preventing premature aging due to excessive heat.

Moreover, TEYU 1500W fiber laser chiller CWFL-1500 features highly precise temperature control of ±0.5℃ and an intelligent temperature control panel, that monitors and adjusts the coolant temperature in real-time, which not only enhances the quality of the laser output but also reduces the potential for thermal-induced errors, thus increasing overall system reliability.

Additionally, the CWFL-1500 fiber laser chiller offers whisper-quiet operation, making it suitable for use in sensitive environments where noise pollution needs to be minimized. Its sleek design and compact footprint make it easy to integrate with existing laser setups. The high-grade components can ensure its durability and longevity. Plus, various alarm devices are built-in to further safeguard the laser chiller and 1500W fiber laser equipment, enhancing operational safety, and reducing losses due to improper operation, enhancing the intelligence, ease and safety of industrial cooling procedures.

To conclude, TEYU 1500W fiber laser chiller CWFL-1500 offers a comprehensive temperature control solution for ensuring the stable and efficient operation of 1500W fiber laser systems. If you are also searching for reliable temperature control solutions for your 1500W fiber laser systems, kindly send an email to sales@teyuchiller.com to get your exclusive cooling solutions now!

Source: https://www.teyuchiller.com/cutting-edge-cooling-solutions-for-1500w-fiber-laser-systems👈