With the continuous progress of technology, the laser tube cutting machine has become a powerful tool in the field of fitness equipment manufacturing, leading the way in innovation and development within the manufacturing industry due to its outstanding performance and effects.

The laser tube cutting machine utilizes a high-energy laser beam, which, after precise focusing, can cut various types of tubes at an extremely high speed. Compared to traditional cutting methods, laser cutting offers higher precision and efficiency. Moreover, it can easily handle tubes of various shapes and specifications, whether they are round, square, or irregular.

Widespread Application in Fitness Equipment Manufacturing

The laser tube cutting machine finds extensive application in the manufacturing of fitness equipment. For instance, the frame of a treadmill needs to withstand the user's weight and the impact force during exercise, demanding high stability and durability. The laser tube cutting machine can precisely cut various components of the frame, ensuring its stability and safety. Additionally, the manufacturing of frames for stationary bikes, dumbbells, and barbells, as well as suspension training systems, also relies on the support of the laser tube cutting machine. It not only enhances production efficiency but also ensures the precision and quality of each component, meeting the usage requirements of users.

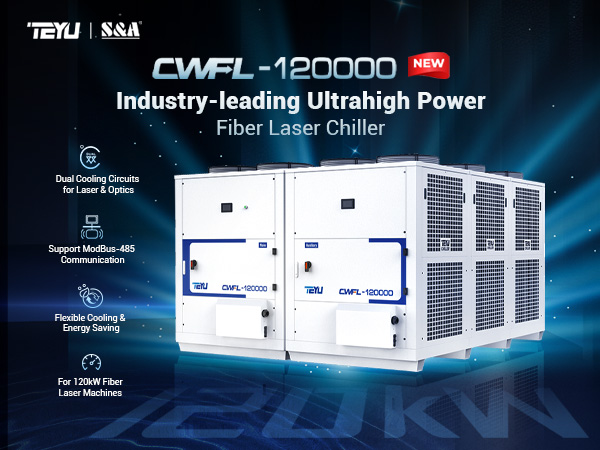

Stable Temperature Control with Laser Chiller

Although the laser tube cutting machine generates a considerable amount of heat during the cutting process, failure to dissipate it promptly may result in tube deformation, affecting cutting quality. TEYU laser chiller, through precise temperature control, rapidly dissipates the heat generated during laser cutting, maintaining a stable temperature in the cutting area. It plays a crucial role in ensuring the quality of laser cutting and the stable operation of the laser equipment.

The laser tube cutting machine, with its efficient and precise cutting technology, contributes to creating more value in the fitness equipment manufacturing industry.

Source: https://www.teyuchiller.com/laser-tube-cutting-machine-in-fitness-equipment-manufacturing