What is a CO2 Laser?

CO2 lasers are a type of molecular gas laser that emits in the long-wavelength infrared spectrum. They rely on a gas mixture as the gain medium, which includes gases like CO2, He, and N2. A CO2 laser comprises a discharge tube pump source and various optical components. In a CO2 laser, the gaseous gain medium CO2 fills the discharge tube and is pumped electrically through DC, AC, or radiofrequency methods to create particle inversion, generating laser light.

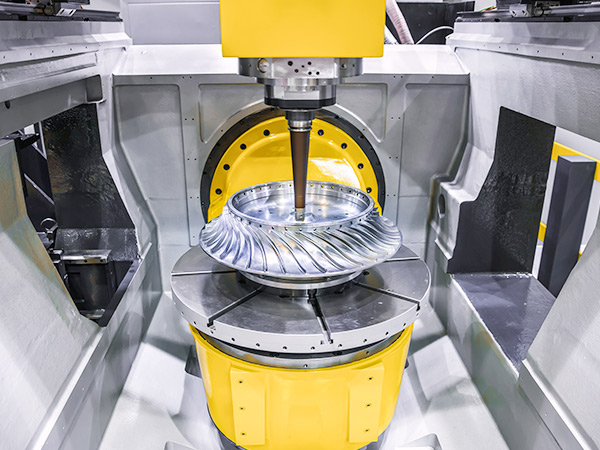

CO2 lasers can emit infrared light with wavelengths ranging from 9μm to 11μm, with a typical emission wavelength of 10.6μm. These lasers typically have average output powers ranging from tens of watts to several kilowatts, with a power conversion efficiency of approximately 10% to 20%. As a result, they are widely used in laser material processing, including cutting and processing materials such as plastics, wood, mold plates, and glass sheets, as well as cutting, welding, and cladding metals like stainless steel, aluminum, or copper. They are also used for laser marking on various materials and 3D laser printing of polymer materials.

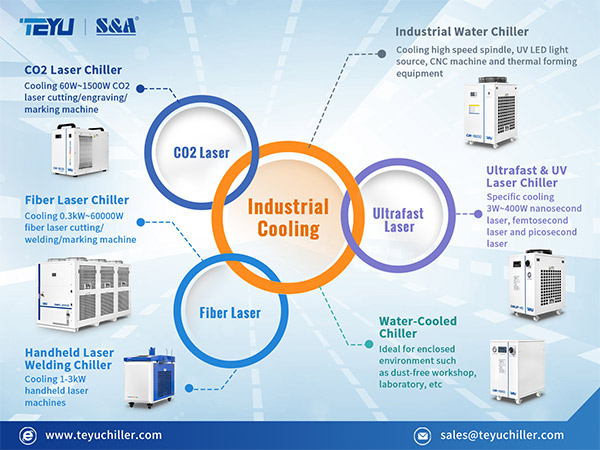

CO2 laser systems are known for their simplicity, low cost, high reliability, and compact design, making them a cornerstone of precision manufacturing. However, the process of pumping energy into a significant volume of CO2 gas generates heat, leading to thermal expansion and contraction in the laser structure, resulting in relative output power instability. Turbulence in the gas-assisted cooling process can also introduce instability. Choosing TEYU S&A laser chillers can ensure stable CO2 laser beam output by providing cooling and temperature control. So how to select the suitable CO2 laser chiller for CO2 laser machines? For instance, an 80W glass CO2 laser tube can be paired with the TEYU S&A chiller CW-3000, while a laser chiller CW-5000 can be selected to cool a 60W RF CO2 laser tube. TEYU water chiller CW-5200 can offer highly reliable cooling for up to 130W DC CO2 laser while the CW-6000 is for 300W CO2 DC laser tube. TEYU S&A CW series CO2 laser chillers do a great job in controlling the temperature of the CO2 laser. They offer cooling capacity ranging from 800W to 42000W and are available in small size and big size. Sizing the chiller is determined by the power or the heat load of the CO2 laser.

For more about TEYU S&A laser chillers selection, you can leave us a message and our professional laser chiller engineers will offer a tailored laser cooling solution for your laser project.

Source: https://www.teyuchiller.com/what-is-a-co2-laser-and-how-to-select-a-co2-laser-chiller