The scorching summer heat is upon us! How can you keep your industrial chiller "cool" and ensure it maintains stable cooling? Today, TEYU S&A engineer team is here to share some expert tips with you~

1. Optimize Operating Conditions

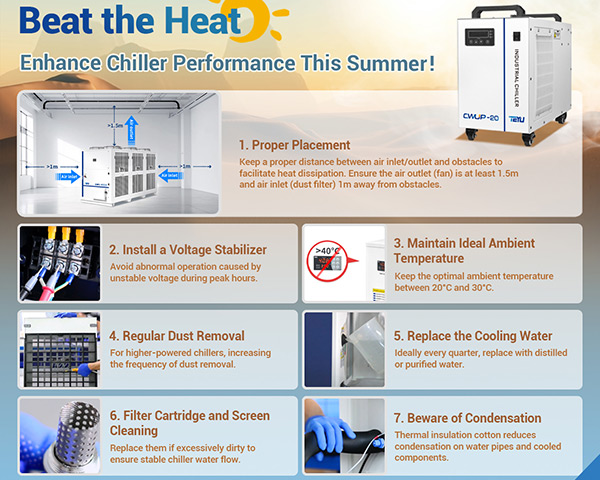

Proper Placement: To maintain good heat dissipation, ensure the air outlet (fan) is at least 1.5 meters away from any obstacles, and the air inlet (dust filter) is at least 1 meter away from obstacles.

Stable Voltage Supply: Install a voltage stabilizer or use a power source with voltage stabilization, which helps avoid the abnormal chiller operation caused by unstable voltage during summer peak hours. It is recommended that the stabilizer’s power capacity be at least 1.5 times greater than the industrial chiller's electric power requirements.

Maintain Ideal Ambient Temperature: If the operating ambient temperature of the industrial chiller exceeds 40°C, it may trigger a high-temperature alarm and cause the industrial chiller to shut down. To avoid this, keep the ambient temperature between 20°C and 30°C, which is the optimal range.

If the workshop temperature is high and affects the equipment’s normal use, consider physical cooling methods such as using water-cooled fans or water curtains to lower the temperature.

2. Regular Maintenance for Industrial Chillers

Regular Dust Removal: Regularly use an air gun to clean the dust and impurities from the industrial chiller's dust filter and condenser surface. Accumulated dust can impair heat dissipation, potentially triggering high-temperature alarms. (The higher the industrial chiller power, the more frequently dusting is required.) Note: When using an air gun, maintain a safe distance of about 15cm from the condenser fins and blow vertically toward the condenser.

Cooling Water Replacement: Replace the cooling water regularly, ideally every quarter, with distilled or purified water. Also, clean the water tank and pipes to prevent deterioration of water quality, which can affect cooling efficiency and equipment lifespan.

Filter Cartridge and Screen Replacement: Filter cartridges and screens are prone to accumulating dirt in industrial chillers, so they require regular cleaning. If they are excessively dirty, replace them promptly to ensure stable water flow in the industrial chiller.

3. Beware of Condensation

In hot and humid summer conditions, condensation can form on water pipes and cooled components if the water temperature is lower than the ambient temperature. This may cause short circuits and even damage the core components of the industrial chiller, impacting production.

It is advised to properly raise the set water temperature according to the ambient conditions and laser usage requirements to reduce condensation.

If you encounter any chiller troubleshooting inquiries, please do not hesitate to contact our customer service team at service@teyuchiller.com.

Source: https://www.teyuchiller.com/keep-industrial-chillers-stable-cooling-in-hot-summer