In the field of CNC machining, CNC machining centers, engraving and milling machines, and engravers are three common types of equipment. Although they all rely on computer numerical control, their structures, power systems, machining capabilities, and cooling needs differ greatly. Understanding these differences and selecting the right cooling system is essential for maintaining machining accuracy, extending equipment lifespan, and ensuring long-term operational stability.

Core Differences Between the Three Machines

CNC Machining Center

A CNC machining center is designed for heavy-duty cutting and precision machining of hard metals. It features a rigid bed structure and high-torque spindles ranging from several kilowatts up to tens of kilowatts, with speeds typically between 3,000 and 18,000 rpm. Equipped with an automatic tool changer (ATC) that can hold more than 10 tools, it supports complex, continuous operations. These machines are mainly used for automotive molds, aerospace parts, and heavy mechanical components.

Engraving and Milling Machine

Engraving and milling machines bridge the gap between machining centers and engravers. With moderate rigidity and spindle power, they typically run at 12,000–24,000 rpm, offering a balance between cutting strength and precision. They are ideal for processing aluminum, copper, engineering plastics, and wood, and are commonly used in mold engraving, precision part production, and prototype making.

Engraver

Engravers are lightweight machines built for high-speed precision work on soft, non-metallic materials. Their ultra-high-speed spindles (30,000–60,000 rpm) deliver low torque and power, making them suitable for materials like acrylic, plastic, wood, and composite boards. They are widely used in advertising sign making, craft engraving, and architectural model production.

Cooling Requirements and Recommended Solutions

For CNC Machining Centers

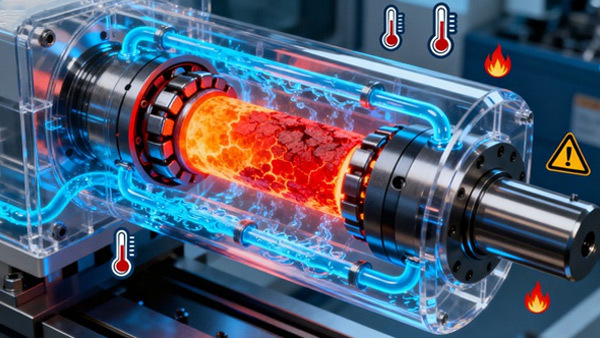

Due to their heavy cutting load, machining centers generate significant heat from the spindle, servo motors, and hydraulic systems. Uncontrolled heat can cause spindle thermal expansion, affecting machining accuracy. A high-capacity industrial chiller is therefore essential.

TEYU's CW-7900 industrial chiller, with 10 HP cooling capacity and ±1°C temperature stability, is engineered for large-scale CNC systems. It ensures precise temperature control even under continuous high-load operation, preventing thermal deformation and guaranteeing stable machining performance.

For Engraving and Milling Machines

These machines require a dedicated spindle chiller to prevent thermal drift at high spindle speeds. Prolonged heat buildup can affect machining surface quality and component tolerances. Based on the spindle power and cooling demand, TEYU's spindle chillers provide stable temperature regulation to keep machining consistent and precise over long working periods.

For Engravers

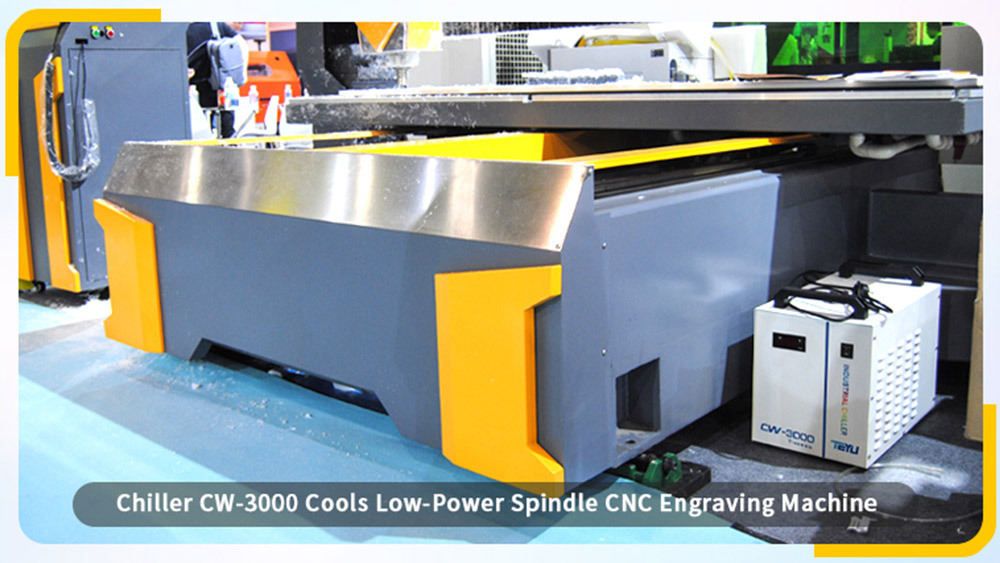

Cooling requirements vary depending on spindle type and workload.

Low-power air-cooled spindles working intermittently may only need simple air cooling or a CW-3000 heat-dissipating chiller, known for its compact design and cost-effectiveness.

High-power or long-running spindles should use a refrigeration-type water chiller like the CW-5000, providing effective cooling for continuous operation.

For laser engravers, the laser tube must be water-cooled. TEYU offers a range of laser chillers designed to ensure consistent laser power and extend laser tube life.

TEYU Industrial Chillers— Professional CNC Cooling Solutions

With 23 years of expertise in industrial refrigeration, TEYU Chiller Manufacturer offers over 120 chiller models compatible with a wide range of CNC and laser systems. Our products are trusted by manufacturers in more than 100 countries and regions, with a shipment volume of 240,000 units in 2024.

TEYU CNC Machine Tool Chiller Series is engineered to meet the unique cooling requirements of CNC machining centers, engraving and milling machines, and engravers, delivering precision, reliability, and long-term performance for every type of machining application.