As the era of "light" arrives, laser light sources continue to evolve, including fiber lasers, pulsed lasers, and ultrafast lasers. CO2 laser tubes, with their high efficiency, high power, and excellent beam quality, are widely used in industrial, medical, and precision processing fields.

How CO2 Laser Tubes Work

The operating principle of CO2 laser tubes is based on the vibrational energy level transitions of carbon dioxide molecules. When an electric current passes through the laser tube, it excites the molecules, causing energy transitions and emitting laser light. We will analyze the differences and applications of two types of CO2 laser tubes: EFR laser tubes and RECI laser tubes.

While both types operate on similar principles, their main differences lie in the excitation method and laser characteristics:

EFR Laser Tubes: EFR laser tubes use an electric current to excite the gas, providing stable output power and excellent beam quality, making them suitable for a variety of laser processing tasks.

RECI Laser Tubes: RECI laser tubes use heat generated by light waves to excite the gas, producing a pure, evenly distributed laser beam. This makes them ideal for precision processing and medical applications where laser quality is of utmost importance.

Applications of EFR and RECI Laser Tubes

EFR Laser Tube Applications: 1)Laser Engraving: Suitable for engraving various materials such as wood, plastic, and metal. 2)Laser Cutting: Effective for rapid cutting of materials like metal, glass, and textiles. 3)Laser Marking: Provides permanent markings on products.

RECI Laser Tube Applications: 1)Precision Processing: Delivers high-precision cutting and engraving for electronic component manufacturing. 2)Medical Equipment: Enables precise laser operations in surgical and therapeutic procedures. 3)Scientific Instruments: Provides a stable and high-quality laser source for research work.

Cost-Effectiveness Analysis of EFR and RECI Laser Tubes

EFR Laser Tubes: With their lower initial cost and maintenance expenses, they are ideal for users with budget constraints or specific cost considerations.

RECI Laser Tubes: Although they have a higher initial cost, their superior quality and long-term stability ensure excellent performance, potentially offering better cost-effectiveness over time.

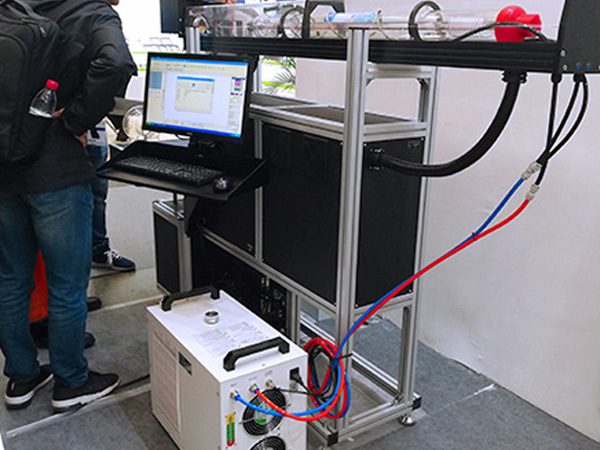

The Role of Water Chillers in CO2 Laser Systems

During high-power laser operations, the heat generated by the laser tubes can affect performance and longevity. Therefore, a water chiller is essential for maintaining stability and prolonging the lifespan of the CO2 laser tubes. TEYU CO2 laser chillers provide both constant temperature and intelligent temperature control modes, allowing for on-demand switching to ensure the stable and efficient operation of CO2 laser systems.

When choosing a CO2 laser tube, users should make decisions based on their application needs, budget, and laser quality requirements. Whether opting for an EFR or a RECI laser tube, pairing it with a suitable water chiller is crucial for ensuring long-term, stable operation.

Source: https://www.teyuchiller.com/co2-laser-technology-efr-laser-tubes-and-reci-laser-tubes👈

.jpg)