Spring humidity can be a threat to laser equipment. During the rainy season or in high-humidity workshops, condensation can form on laser equipment surfaces. This can lead to everything from system shutdowns to severe damage to core components. But don't worry—TEYU S&A Chiller is here to help you tackle the dew crisis with ease.

Dewing Crisis: The "Invisible Killer" for Lasers

1. What is Dewing?

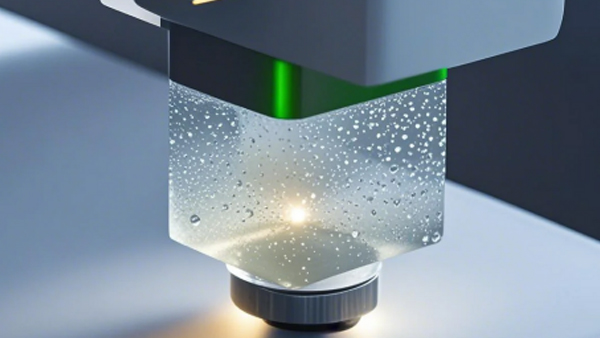

When a laser system's surface temperature drops drastically due to traditional cooling methods, and the environmental humidity exceeds 60%, with the device temperature falling below the dew point, the water vapor in the air condenses into droplets on the equipment surface. It is similar to condensation forming on a cold soda bottle—this is the "dewing" phenomenon.

2. How Dewing Affects Laser Equipment?

Optical lenses fog up, leading to scattered beams and reduced processing accuracy.

Moisture short-circuits the circuit boards, causing system crashes and even potential fires.

Metal components rust easily, increasing maintenance costs!

3. The 3 Major Issues with Traditional Humidity Control Solutions

Air Conditioner Dehumidification: High energy consumption, limited coverage.

Desiccant Absorption: Requires frequent replacement and struggles with continuous high humidity.

Equipment Shutdown for Insulation: While it alleviates dewing, it affects production efficiency and is only a temporary fix.

Laser Chiller: The "Key Weapon" Against Dewing

1. Proper Water Temperature Settings of Chillers

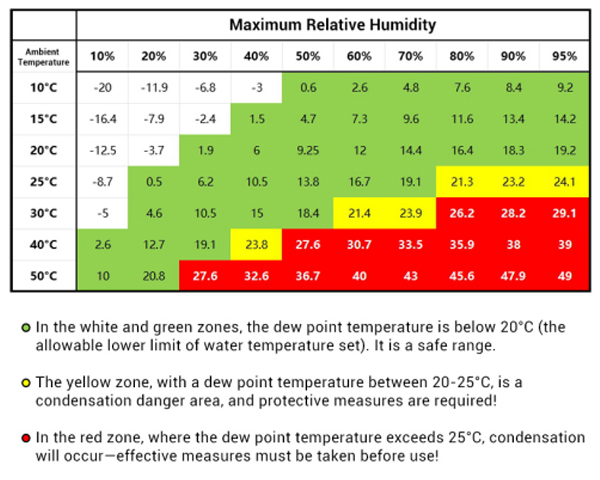

To effectively prevent dew formation, set the water temperature of the chiller above the dew point temperature, considering both the actual working environment's temperature and humidity. The dew point varies with ambient temperature and humidity (please refer to the chart below). This helps avoid significant temperature differences that could lead to condensation.

2. Proper Water Temperature of the Optics Circuit of the Chiller to Protect the Laser Head

If you're unsure how to adjust the water temperature through the chiller controller, feel free to contact our technical support team via service@teyuchiller.com. They will patiently provide you with professional guidance.

What to Do After Dewing?

1. Power down the equipment and use a dry cloth to wipe off the condensed water.

2. Use exhaust fans or dehumidifiers to reduce humidity.

3. Once the humidity drops, preheat the equipment for 30-40 minutes before restarting to prevent further condensation.

As spring humidity sets in, it's crucial to focus on moisture prevention and maintenance for your laser equipment. By ensuring stable operation, you can keep your production running smoothly.

Source: https://www.teyuchiller.com/how-to-protect-your-laser-equipment-from-dew-in-spring-humidity