As manufacturing moves toward greener and smarter production, laser cleaning is rapidly becoming a mainstream technology. Traditional methods such as chemical solvents, sandblasting, and mechanical abrasion are increasingly constrained by environmental, safety, and efficiency concerns. In contrast, laser cleaning delivers non-contact operation, zero consumables, and exceptional controllability, making it a signature process of sustainable manufacturing.

Global Market Landscape and Growth Outlook

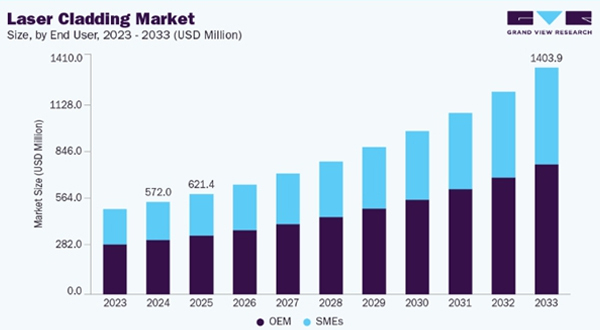

According to MarketsandMarkets, the global laser cleaning equipment market is valued at roughly USD 700 million in 2024 and is projected to grow at a CAGR of 4%–6% through 2033. Mordor Intelligence expects the market to surpass USD 2 billion by 2030.

The global market demonstrates clear regional characteristics. North America, led by the United States, drives innovation through its defense, aerospace, and high-end automotive sectors, supported by stringent environmental regulations. Europe, guided by the Green Deal framework, prioritizes energy efficiency, certification, precision engineering, and renewable energy applications. These mature markets consistently demand high reliability, intelligent control, and seamless integration with automated production.

In Asia and other emerging regions, growth is propelled by broad-based manufacturing upgrades. China stands out as a powerful growth engine, supported by robust industrial policies and surging demand from new-energy and semiconductor sectors. A competitive local supply chain and strong cost advantages are accelerating the rise of regional manufacturers and reshaping global competition. It is shown that the Chinese laser cleaning equipment market expanded from roughly RMB 510 million in 2021 to about RMB 780 million in 2024, representing an average annual growth rate of more than 13% and accounting for roughly 30% of the global market.

Laser Cleaning Evolution: From Light Sources to Intelligent Systems

Laser cleaning has progressed through three stages: handheld tools, automated cleaning stations, and today's smart cleaning systems integrated with robotics and AI vision.

* Light sources: Fiber lasers dominate due to stability and low maintenance, while the adoption of picosecond and femtosecond ultrafast sources is pushing cleaning precision into microelectronics and semiconductor-level applications.

* Control systems: Modern equipment uses AI to identify contaminants, adjust power and focus in real time, and perform closed-loop cleaning with higher energy efficiency. Remote monitoring and cloud-based data management are becoming standard.

Expanding Laser Cleaning Applications Across Industries

The application landscape of laser cleaning is expanding far beyond mold cleaning and rust removal. It is evolving into a versatile, cross-industry process used across high-value industrial sectors. In automotive and rail transportation—together representing around 27 percent of the global market—laser cleaning is widely applied for pre-weld treatment, paint removal, and component refurbishment, improving throughput and material utilization. Aerospace relies on its non-destructive nature for coating removal on engine blades, composite surface preparation, and aircraft maintenance, meeting strict regulatory standards.

New-energy and semiconductor manufacturing represent the fastest-growing segments. In photovoltaics and battery production, laser cleaning enhances conversion efficiency and energy density by removing oxides and residues with micron-level precision. Semiconductor fabs use ultraclean, stress-free laser processes for micro-contamination removal on wafers and precision components. The technology is also proving invaluable in cultural heritage restoration, shipbuilding, and nuclear decommissioning.

Its transition from a "specialized device" to an "industrial foundational process" underscores how laser cleaning is becoming a core enabler of global smart manufacturing and green transformation.

Future Directions for the Global Laser Cleaning Industry

Key development trends include:

① Intelligence: AI-driven recognition and automated path planning

② Modular design: Standardized components for easy maintenance and upgrades

③ System integration: Deep coordination with robotics and vision systems

④ Service-oriented models: Shifting from equipment sales to turnkey solutions

⑤ Sustainability: Higher energy efficiency and lower operating consumption

Where Light Shines, Clean Surfaces Follow

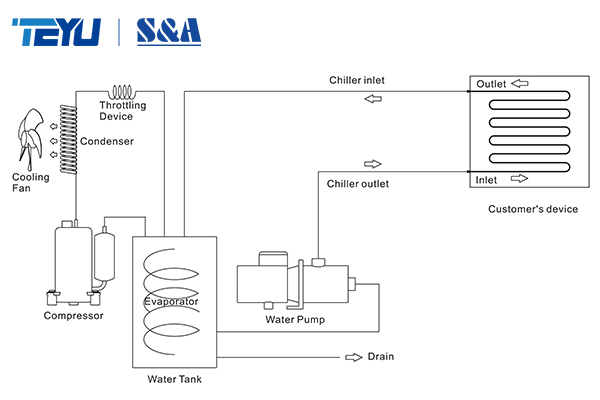

Laser cleaning is more than a technological upgrade—it reflects a structural shift in how modern industries pursue cleanliness, sustainability, and process stability. As laser cleaning systems move toward higher power, greater precision, and continuous operation, thermal management becomes a decisive factor in ensuring beam stability, process consistency, and equipment lifespan.

As a specialized chiller manufacturer with over two decades of experience in industrial laser cooling, TEYU Chiller provides precision temperature control solutions tailored for fiber, ultrafast, and high-duty-cycle laser systems used in laser cleaning applications. Through closed-loop cooling design, intelligent temperature control, and proven reliability across global manufacturing environments, TEYU supports laser equipment manufacturers and end users in maintaining stable performance under demanding operating conditions. By working closely with laser system integrators and automation solution providers, TEYU continues to act as a dependable chiller supplier behind next-generation laser cleaning technologies—quietly safeguarding process quality as industries move toward smarter, greener production.

Source: https://www.teyuchiller.com/laser-cleaning-equipment-market-outlook-and-emerging-trends.html