Laser processing technique is now pretty common in a wide variety of industries. For mold industry, although laser cutting and laser welding seem to not find its proper use for the moment, laser cleaning has become increasingly used in mold surface treatment, outperforming traditional cleaning.

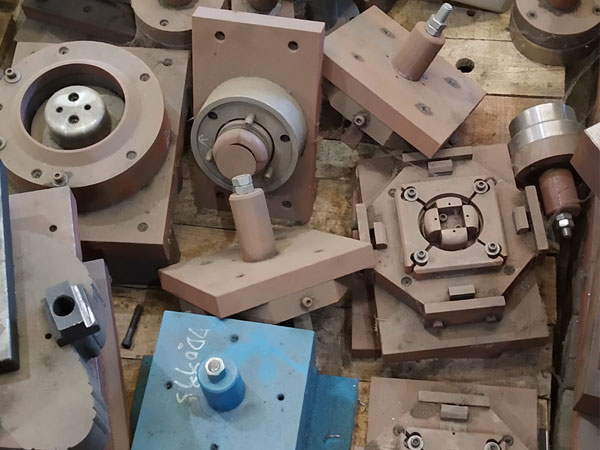

When it comes to mold, it’s quite easy to understand. From the cake making to big industrial machine, it requires mold to finish. Our country has the world’s biggest manufacturing business and every industrial machine has various types which require different molds.

Since mold needs to be in contact with high temperature material or needs to face the punch or stress, it is often made from metal.

In the actual use, there are often some urgent problems that need to be solved in mold. And the most important one is the cleaning of the mold. Some metal molds are used to be the prototyping of high temperature hot melting material. When the products have finished and are taken out from the molds, there are often material residue left on the molds. This requires people to clean the molds, for this will affect the next product making, but that would be quite time consuming.

What’s more, molds are easy to get rusty. Since most of the industrial molds are made from steel, they would become rusty after being used for a period of time. And molds need to be cleaned properly before they are used on the machine. However, traditional cleaning would cost a huge labor and cost, which is very bad for the manufacturers.

But ever since laser cleaning is introduced in mold cleaning, things have become different. Laser cleaning uses high power and high frequency laser light on the mold surface so that the residue, rust, oi stain, etc. can evaporate from the mold surface or become particle instantly. You might see the result of laser cleaning. When the laser beam moves along on the material surface, the surface can become quite clean within seconds.

Nowadays, laser cleaning can be performed effectively on flat surface, curved surface, hole and gap. The common handheld laser cleaning machine is already quite effective on removing rust from general metal molds and the cleaning time is only 1/10 of traditional cleaning. Besides, many manufacturers are now considering installing laser cleaning machines on the mold production lines to realize monitoring and automatic cleaning the material residue on the molds, which is very efficient.

Laser cleaning technique has become more and more mature. From the original 200W to nowadays 2000W, laser cleaning machine can perform more and more demanding cleaning. Therefore, it has a great future in mold industry. For laser cleaning machines with different powers, S&A Chiller can provide suitable laser water chillers to match them and the cooling capacity can be up to 30KW. We have been helping many laser cleaning machine users to solve the overheating problem.

S&A Chiller has been developing and producing laser water chillers for 20 years. They cover almost every laser application. We are constantly keeping an eye on the new application in laser industry and developing chillers that match them. With constant innovation, we have become a well-known brand in the laser cooling market.

For our detailed laser water chiller models, click https://www.teyuchiller.com/products

没有评论:

发表评论