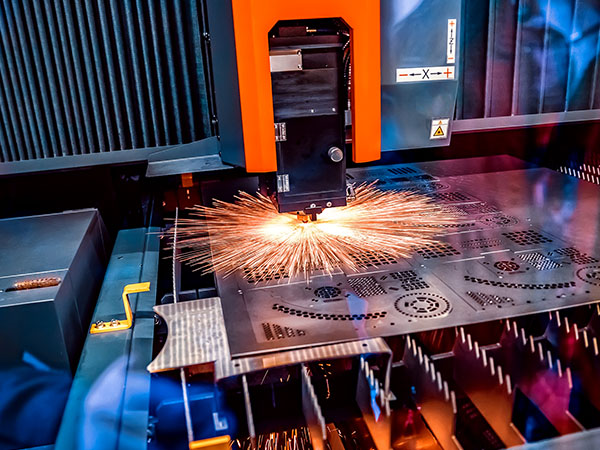

The metal processing industry has been ushering in waves of change in today’s society with rapid technological development. Metal processing is mainly the cutting of metal materials. For the need of production, there is increasing cutting demand for metal materials of different textures, thicknesses and shapes. And the requirements for the workpiece cutting process are higher and higher. Traditional cutting can no longer satisfy the needs and is replaced by laser cutting, which is the main technology in the metal processing industry.

Compared with traditional cutting methods, what advantages does laser cutting technology have?

1. Laser cutting technology features higher cutting precision, faster cutting speed and smooth & burr-free cutting surface. Non-contact processing between the laser head and the workpiece will not cause scratches on the workpiece surface, without the step of secondary grinding. The high-precision processed product can improve the material utilization rate and save production costs.

2. Cost-saving and efficient. Professional computer-controlled cutting software supports cutting into any complex graphics and words, which greatly saves labor and time costs for enterprises to realize highly automatic processing, ensure good cutting quality and improve production efficiency.

3. Wide application. Laser cutting machine, with unmatchable production advantages compared with other traditional cutting processes, is not only applicable to precise component processing but also large metal plate pipe processing.

Although laser metal cutting has huge advantages over traditional cutting methods, along with the higher requirements, it still has several major pain points: (1) Higher power laser cutting devices are chosen to satisfy the processing thickness needs; (2) Batch processing of high-reflectivity materials often leads to laser damage; (3) The processing efficiency of non-ferrous materials is low.

The appearance of the laser scanning cutting machine: The laser scanning machine newly developed by Bodor Laser adopts a self-developed optical system device, optical path space programming technology and patent process algorithm to achieve: (1) At the same power, the ultimate cutting thickness has been greatly increased; (2) At the same power and thickness, the cutting speed has been significantly improved. (3) Fearless of high reflectivity, it solved the problem that high-reflectivity materials can not be processed in scores.

Whether it is the laser cutting machine or laser scanning cutting machine, its cutting principle is to rely on the laser beam irradiation on the surface of the workpiece, so that it can reach the melting or boiling point. Meanwhile, beam-coaxial high pressure gas blows away molten or vaporized metals, during which immense heat is generated thus will affect the workpiece, reducing the quality of processing products. S&A laser chiller can provide laser cutting/laser scanning cutting machines with a reliable cooling solution featuring a constant temperature, constant current and constant voltage. S&A chiller, which can precisely control the temperature and stabilize the beam output to ensure the continuous and stable operation of laser cutting machines, is a good helper in cooling your laser equipment!

Source: https://www.teyuchiller.com/improvement-of-laser-cutting-technology-and-its-cooling-system

没有评论:

发表评论