Laser welding is achieved by using a high-energy beam to transform into heat energy to radiate onto the workpiece, then instantly melting and bonding the material. The speed of laser welding is fast that it can satisfy the needs of continuous mass production. Its advantages such as smooth and beautiful processing workpiece, polish-free treatment can save time and costs for manufacturers. Laser welding has gradually replaced the traditional welding. So what are the main components of a laser welder?

1. Laser welding host

Laser welding host machine mainly produces laser beam for welding, which is made up of power supply, laser generator, optical path and control system.

2. Laser welding auto workbench or motion system

This system is used to realize the movement of laser beam according to the welding track under specific requirements. To realize the automatic welding function, there are 3 control forms: workpiece moves with laser head fixed; laser head moves with workpiece fixed; both laser head and workpiece move.

3. Work fixture

During the laser welding process, laser welding work fixture is used to fix the welding workpiece, making it can be repeatedly assembled, positioned and disassembled, which benefits the automatic welding of the laser.

4. Viewing system

Generic laser welder should be equipped with a viewing system, which is conducive to the accurate positioning during the welding programming process and the effect inspection when welding.

During the operation of the laser machine, a large amount of heat is generated. So water-cooled way is needed to cool down the laser machine and keep it to the proper temperature range, which helps to ensure the laser beam quality and output power, and prolongs the service life of the laser.

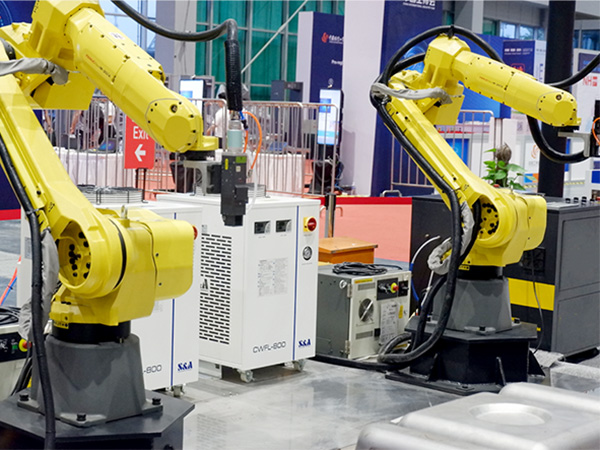

S&A laser welding machine chiller comes with dual temperature control system, while the high temperature circuit cools the laser head and the low temperature circuit cools the laser machine. One device serves several purposes, which saves costs and space. The laser chiller is also equipped with multiple warning protections: time-delay and over-current protection of compressor, flow alarm, ultrahigh/ultralow temperature alarm.

Due to the flexible requirement of laser welding, handheld laser welding machine is popular on the market. Correspondingly, Teyu launches all-in-one handheld laser welding machine chiller, which can be flexibly used matching with your handheld laser welder.

Source: https://www.teyuchiller.com/main-components-of-a-laser-welder

没有评论:

发表评论